Introduction

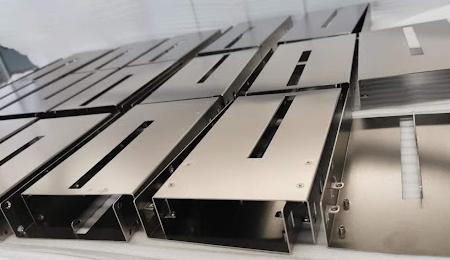

SF2014CH is a highly integrated coil fed laser cutting system, consisting of decoiler, blanking machine, laser cutting machine and automatic stacking device. Senfeng has pushed the thickness limit of coil to 0.55″, which is the first to apply this exclusive technology to practical production and make coil fed for medium-thick metal possible. It’s a flexible coil-fed production line which can be tailor-made to match specific material requirements. Laser blanking line offers many advantages thanks to its use of a coil, such as savings on raw material, consistent work rates and a lower coston labor.

Advantages OF SF2014CH

- Double-sided decoiler: the maximum loading capacity of double-sided decoiler can reach to 66000 lbs. One loading can be processed for longer time, save time and labor on frequent loading.

- The plate positioning and correction device is composed of a correction roller installation slider and a correction roller wheel, which can realize the precise positioning of the plate and improve the efficiency.

- The fully automated assembly line design can achieve zero waste to the greatest extent and improve the utilization rate of the sheet.

Application industries

Medium thick coil laser cutting system, with highly flexible integration, is widely used in various industries including sheet metal processing, machinery manufacturing, auto parts manufacturing, electrical manufacturing, elevator manufacturing, petroleum machinery, food machinery, decoration advertising and so on.