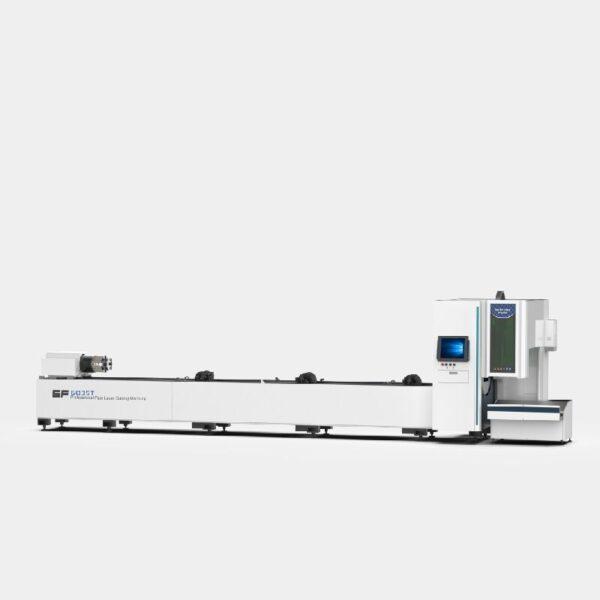

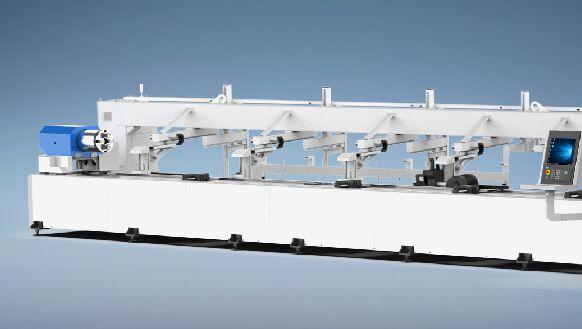

Cut Tubes at Lightning-fast Speed

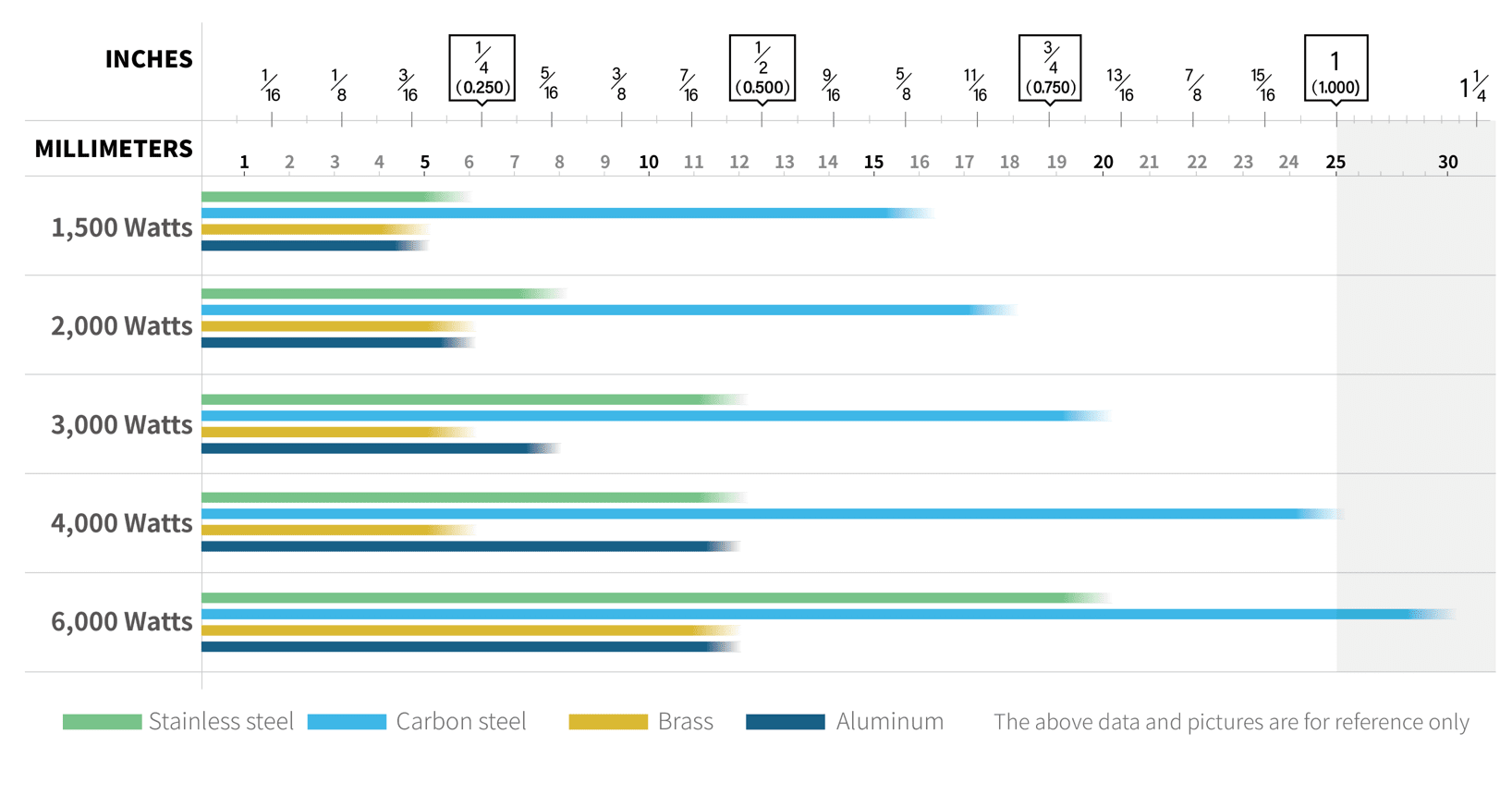

The control system, chucks, cutting head, machine body and self-developed laser generator are well adapted with each other, so as to cut small tube without overburning or adhering slag and large tube fleetly.

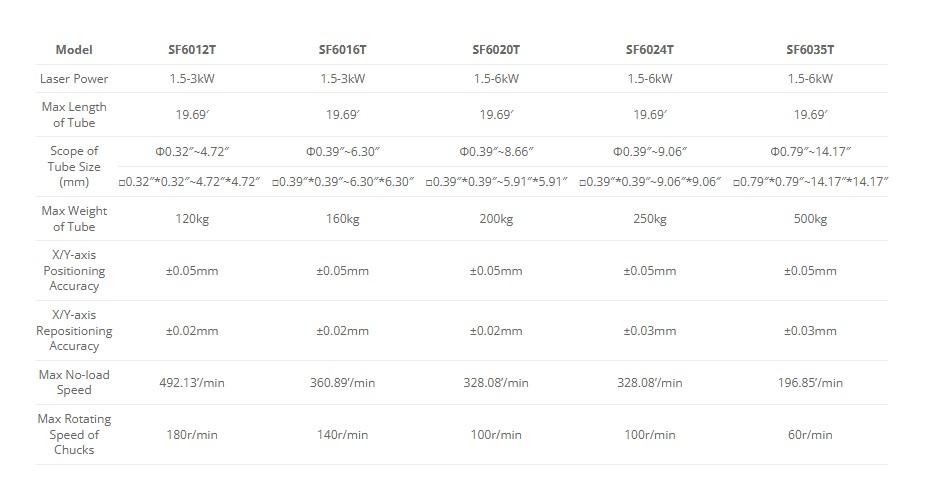

- No-load speed: 196.85′-492.13′

- Acceleration: 120kg-500kg

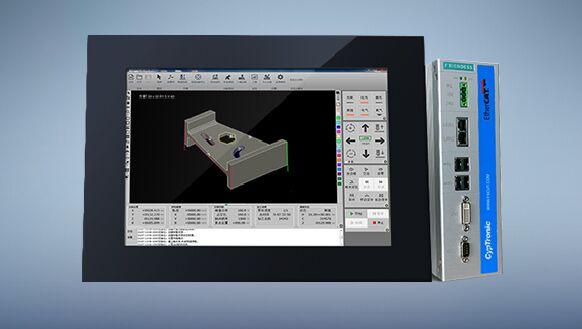

Self-developed Bus-based CNC System

Based on EtherCAT protocol, it is easy for the system to get started only by clicking a button. Its built-in nesting software can nest both single or multiple parts, and import files of different formats in batch.

* Content-rich cutting database

* Co-edge cutting

* Automatic centering

* Corner cutting

High Degree of Automation

The machine comes standard with automatic unloading device to unload 3m long tube. Users may apply for semi-/fully-automatic loading devices as optional accessories, so as to reduce labor intensity during work.

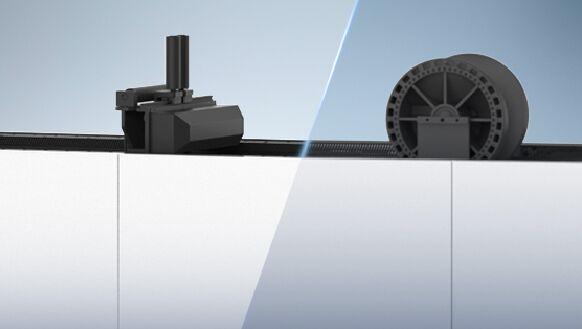

Two Chucks with Shorter Tailing

The chucks are self-centering and high in clamping precision. Pneumatic grippers are adopted to clamp tubes of different shapes, sizes and weights firmly.

- Rotating speed: 60-180r/min

Keep Long Tubes Stable

We offer two kinds of tube support modes. For follow-up support, it usually moves along with rotating tube. In case of vari-pitch support, long tube will be free from cutting deviation caused by its swing up and down.