Introduction

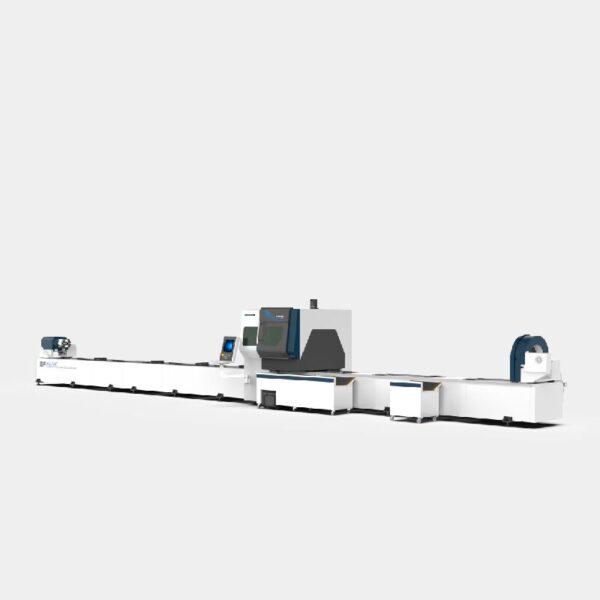

NT is a tube laser cutting machine with larger processing capacity: tube length increased to 39.37′ , cutting different profiles, such as round tube, square tube, rectangular tube, L, U and H profiles. With a moving chuck in the middle, three-chuck design can ensure actual “0” tailing with better accuracy and stable performance. Advanced bus CNC system and cutting software help achieve high-speed flash cutting.

Advantages OF TUBE LASER CUTTER NT Series

- Achieve 39.37′ whole tube loading and cutting. No need to prepare long tube before cutting, save procedure and time, increase efficiency and production capacity.

- Three-chuck clamping: adopting movable two-side chuck to realize actual 0 tailing. With the strong clamping force, there would be no loosening or slipping of long and heavy pipe, which can achieve more stable feeding and more precise cutting.

CUTTING SAMPLES

Cutting material: Carbon steel, stainless steel, aluminum alloy, brass, copper, galvanized steel, silicon steel, electrolytic steel, titanium alloy, manganese alloy, etc

Application industries

Three-chuck tube cutting machine is widely used in aerospace, metal fabrication, machine manufacturing, rail transport, automobile manufacturing and food machinery.