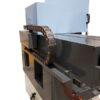

- Cost iron transmission and machine body

- Automatic Centering System

- Servo Control

- Easy programming and 4(four) different menu set up LCD Touch Screen

- A special head with a joint that can adjust it self according to valve seat s automatically

- Speed adjustable spindle rotation

- Speed limit on manual control

- Electronic system that you can run in required speed

- Electronic system that supplies soundless and practical working

- Electronic feeding scale feature to follow the given feeds

- Vacum system and vacuum meter on touch screen

- Easy Programing and data save on memory

- Affluent equipment variety

- Pneumatic(Air Floating) table

- Pneumatic(Air Floating) workhead

- Pneumatic(Air Floating) boring spindle

- Cabin covers and closet cupboards for pilots and other tools.

- Special up to 180◦ (Angle) Cylinder Head connection fixtures.

- Electronic delicate indicator of cutting deep.

| Model | KR 1600 |

|---|---|

| Manufacturer | POLEKS |

| Type of drive system | air / electrical |

| The maximum length of the processed cylinder head, mm | Not limited |

| Max.Cylinder head placing capacity (Width), mm | 600 |

| Max.Cylinder head placing capacity (Height), mm | 520 |

| Max.Boring capacity ( with standard tools) , mm | 70 |

| Max.Boring capacity ( with extra tools) , mm | 120 |

| Min.Boring capacity , dia | 16 |

| Max. Table traverse travel (forward-backward movement), mm | 260+130 |

| Workhead travel -Lengthwise (with parking area), mm | 1440 |

| Workhead travel Sphere-cylinder travel, mm | 30 |

| Max. spindle inclination, degree | 15 |

| Spindle travel (down-up), mm | 190 |

| Spindle motor power (servo motor with servo reducer) , Kw | 0.75 |

| Spindle rotation speed, rpm | 0-500 |

| Electric System , V | 380-24-3 |

| Pneumatic supply, bar | 6 |

| Max. air flow, l/mn -CFM | 400/15 |

| Noise level at 500 RPM, Dda | 40 |

| Machine dimensions (DShV), mm | 2200x970x2300 |

| Net weight, kg | 1700 |

Equipment

Complete machine

|

1 |

| Set Single Axis Roll-Over Fixture | 1 |

| Carbide Bit Sharpener(withing grinding wheel Ø 100) | 1 |

| Vacum Testing Device | 1 |

| Pad With Foam For Vacuum Tester (Ø50mm) | 1 |

| Pad With Foam For Vacuum Tester (Ø70mm) | 1 |

| Pad With Foam For Vacuum Tester (50x80mm) | 1 |

| Pad With Foam For Vacuum Tester (70x80mm) | 1 |

| Tool Setting Device | 1 |

| Bubble Level For Pılot Dia.Shank Ø 9.52 mm | 1 |

| Torx T8 Screw Driver | 1 |

| Allen Key(T) 3 mm. | 1 |

| Allen Key(T) 2.5 mm. | 1 |

| Valve Seat Angle Control Device | 1 |

| Bit Holder ( 16-30) | 1 |

| Bit Holder ( 16 -30) | 1 |

| Bit Holder ( 28-42) | 1 |

| Bit Holder (40-58) | 1 |

| 3 Angle Cutting Carbide Bit ( 30ºx1.5 mm.) | 1 |

| 3 Angle Cutting Carbide Bit ( 30ºx2.0 mm.) | 1 |

| 3 Angle Cutting Carbide Bit (45ºx1.5 mm.) | 1 |

| 3 Angle Cutting Carbide Bit (45ºx2.0 mm.) | 1 |

| 3 Angle Cutting Carbide Bit (45ºx2.5 mm.) | 1 |

| 3 Angle Cutting Carbide Bit (30ºx2.5 mm.) | 1 |

| 3 Angle Cutting Carbide Bit (45ºx1.3 mm.) | 1 |

| 90 Degree Flat Cutting Bit | 1 |

| 20 Degree Single Angle Cutting Bit | 1 |

| 30 Degree Single Angle Cutting Bit | 1 |

| 45 Degree Single Angle Cutting Bit | 1 |

| Sleeve Parallels (50×30 x240mm) | 1 |

| Flat Parallels (50x30x240mm) | 2 |

| Flat Parallels (40x20x310mm) | 2 |

| Cast-Iron Parallels (50x60x350mm) | 2 |

| Portable quick clamb apparatus | 2 |

| Carbide Pilot Ø4,98 mm / Ø9,52 – L : 165mm | 1 |

| Carbide Pilot Ø5,00 mm / Ø9,52 – L : 165mm | 1 |

| Carbide Pilot Ø5,48 mm / Ø9,52 – L : 165mm | 1 |

| Carbide Pilot Ø5,50 mm / Ø9,52 – L : 165mm | 1 |

| Carbide Pilot Ø5,98 mm / Ø9,52 – L : 165mm | 1 |

| Carbide Pilot Ø6,00 mm / Ø9,52 – L : 165mm | 1 |

| Carbide Pilot Ø6,98 mm / Ø9,52 – L : 165mm | 1 |

| Carbide Pilot Ø7,00 mm / Ø9,52 – L : 165mm | 1 |

| Carbide Pilot Ø7,98 mm / Ø9,52 – L : 165mm | 1 |

| Carbide Pilot Ø8,00 mm / Ø9,52 – L : 165mm | 1 |

| Tapered Steel Ø4,98 mm/ Ø9,52 – L : 165mm | 1 |

| Tapered Steel Ø5,00 mm/ Ø9,52 – L : 165mm | 1 |

| Tapered Steel Ø5,48 mm/ Ø9,52 – L : 165mm | 1 |

| Tapered Steel Ø5,50 mm/ Ø9,52 – L : 165mm | 1 |

| Tapered Steel Ø5,98 mm/ Ø9,52 – L : 165mm | 1 |

| Tapered Steel Ø6,00 mm/ Ø9,52 – L : 165mm | 1 |

| Tapered Steel Ø6,01 mm/ Ø9,52 – L : 165mm | 1 |

| Tapered Steel Ø6,98 mm/ Ø9,52 – L : 165mm | 1 |

| Tapered Steel Ø7,00 mm/ Ø9,52 – L : 165mm | 1 |

| Tapered Steel Ø7,01 mm/ Ø9,52 – L : 165mm | 1 |

| Tapered Steel Ø7,98 mm/ Ø9,52 – L : 165mm | 1 |

| Tapered Steel Ø8,00 mm/ Ø9,52 – L : 165mm | 1 |

| Tapered Steel Ø8,01 mm/ Ø9,52 – L : 165mm | 1 |

| Tapered Steel Ø8,25 mm/ Ø9,52 – L : 165mm | 1 |

| Tapered Steel Ø8,50 mm/ Ø9,52 – L : 165mm | 1 |

| Tapered Steel Ø8,98 mm/ Ø9,52 – L : 165mm | 1 |

| Tapered Steel Ø9,00 mm/ Ø9,52 – L : 165mm | 1 |

| Tapered Steel Ø9,50 mm/ Ø9,52 – L : 165mm | 1 |

| Tapered Steel Ø10,00 mm/ Ø9,52 – L : 165mm | 1 |

| Tapered Steel Ø11,00 mm/ Ø9,52 – L : 165mm | 1 |

| Tapered Steel Ø11,98 mm/ Ø9,52 – L : 165mm | 1 |

| Tapered Steel Ø12,00 mm/ Ø9,52 – L : 165mm | 1 |

Video

Ask a question to a specialist