Valve Seat Boring Machines

Showing all 5 results

Sorting:

Manufacturers:

Manufacturers

All ManufacturersSince its inception, the car industry has innovated at revolutionary speed. The design and engineering of vehicles is continually taking us further, faster, and more safely into the future. A vital cog of the industry is in engine and car parts remanufacturing, a sector that is currently worth just under USD 55,000 million. With factors such raw materials shortages and increased sustainability focuses pushing further growth, the reconditioned auto parts industry is anticipated to reach USD 91 billion by the end of 2026. Remanufactured engine parts cost between 50% and 75% of their original value, and provide the same level of performance. This offers large revenue incentives for businesses involved in their reconditioning. CNC machining and the drive towards automated processes that bolster machining accuracy, speed, and repeatability, is transforming the workflow and profitability of many auto businesses. The key is in making a considered purchase decision on all equipment. MachTrade auto machining sales, service, and repair company is dedicated to assisting customers to buy right, use well, and maintain wisely. Here’s the company’s best advice guide for valve seat cutting machine purchase and use.

Contents:

Valve seat cutting machine uses

MachTrade’s guide to valve seat grinding machine selection

The MachTrade valve seat boring machine model line-up

Top manufacturer valve seat boring tool

MachTrade CNC valve seat cutting machine FAQs

1) Valve seat cutting machine uses

If you’re running an auto shop, it’s quite likely that a valve seat grinding machine will be one of your business’ most important investments. The valve seat and valves are responsible for sealing off the combustion chamber of an engine’s cylinder, absorbing a portion of the heat from the valve to stop its impact burying into the cylinder head. The high incidence of cylinder heads cracking or being damaged, makes replacing valve seats a frequent necessity. A valve seat boring tool enables burnt or worn valve seats to be reconditioned and returned to function rather than discarded.

As cylinder head servicing and valve seat boring are commonly and frequently performed auto re-manufacture activities, your firm’s valve seat machine should be as high-performance and durable as possible. Making an informed choice at point of purchase, as well as engaging with a reliable service and repair team to keep you up and running well into the future, are the top tips for getting the most out of your valve seat resurfacing machine. MachTrade’s comprehensive online portal and mobile sales and servicing help you to do both.

2) MachTrade’s guide to valve seat grinding machine selection

MachTrade helps you make the most out of your search for a valve seat cutting machine by providing an online platform with detailed product guides as well as dynamic pricing tools and professional advice. Whether your business is in a position to purchase a new valve seat cutter machine or upgrade existing machinery, MachTrade has the solution.

A valve seat boring machine is high value equipment intended to withstand rigorous, frequent, and long-term usage. As such, investing in quality is paramount, as is engaging with scheduled life-span extending maintenance and repair work. MachTrade provides convenient online sales and product delivery options, complemented by mobile on-site servicing and repairments.

When it comes time to have your valve and seat machine serviced, or if you have any unexpected operational issues that require fixing, simply contact MachTrade. An expert service and repair team will arrive on-site, causing minimal disruption to your operations. MachTrade’s longstanding relationships with its manufacturing suppliers guarantee a ready supply of any spare parts that may be required.

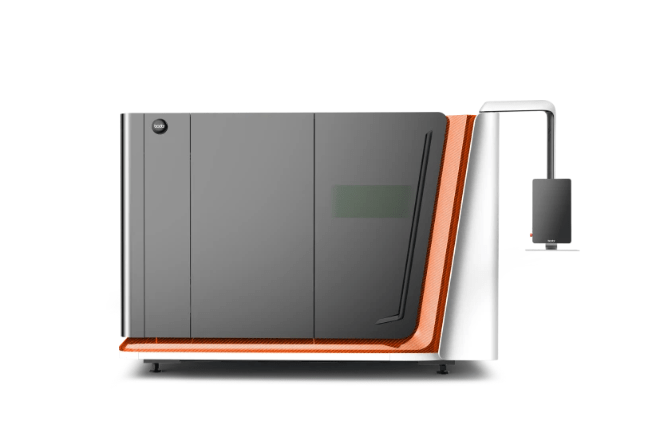

3) The MachTrade valve seat boring machine model line-up

MachTrade’s top tooling technicians recommend that a superior valve seat boring machine design achieves minimal radial imbalance of its system’s cutters, improving the concentricity of valve guide to seat. The MachTrade catalog of valve seat machine models have been selected with this in mind.

Aligned with top manufacturers of machining tools, POLEKS and SJMC, MachTrade’s range includes the POLEKS KR 1600-S model with heavy duty cast iron transmission and machine body, automatic centering system, easily navigable menu controls and saving of programs, soundless operation, speed adjustable spindle rotation, pneumatic table, workhead, and boring spindle, and so much more.

MachTrade also supplies a range of SJMC models that all feature high-level accuracy whilst boasting specificities in engine suitability. The compact BV60 is perfectly suited to motorcycle and car engines and compound cylinder engines, while the BV90 can be purposed for machining valve seats from the smallest to the biggest diameter, rendering it accurate for anything from micro engines up to very large stationery ones. Like further advice on the perfect fit CNC valve seat cutting machine to scale your business, ask a specialist online at MachTrade.

4) Top manufacturer valve seat boring tool

MachTrade’s valve seat grinding machine catalog has been curated by company representatives all of whom have extensive experience working within the automobile industry. This means that every valve seat cutting machine for sale through MachTrade has the company’s endorsement as a high-performance and value for money machining option. Take a look at the in depth product specifications and instructional video guides, and if you’ve got any questions on a particular model submit it online and a MachTrade customer service member will get right back to you.

Similarly, if you’d like a best offer price estimate on a CNC valve set machine model, there’s a chat function for that too. MachTrade aims to be much more than a marketplace, offering customers a valve seat grinding machine for sale process that incorporates competitive purchase pricing, warranties on all units sold, and favorable post-warranty repair or servicing.

5) MachTrade CNC valve seat cutting machine FAQs

Why is purchasing a cylinder head valve seat cutting machine through MachTrade a better option than buying a used machine?

There are many advantages to purchasing through MachTrade as opposed to sourcing a used valve seat machine for sale on a marketplace. As a customer service oriented company, MachTrade specialists are always on hand to provide unbiased pre-purchase advice. MachTrade also offers a peace of mind warranty of all machines sold. Buying a used product direct from a seller or via a marketplace usually provides no consumer protection in the event of faulty or malfunctioning goods. With MachTrade you know all your servicing needs, and repairs, will be attended to, onsite and at your convenience.

Why does MachTrade not sell more brands, for example a rottler valve seat machine?

MachTrade has developed firm partnerships with manufacturers it believes offer machinery and tools that represent the highest quality, performance, and value for money on today’s market. In doing so, MachTrade is not only able to extend its best pricing to customers but also guarantees a steady supply of any spare parts that may be required for future maintenance and repairs, and service teams who are experts at working across all catalog model machines.

The scale of your auto business, the range of engines you work on, future expansion plans and personal preferences, will all play a role in choosing the right valve seat boring machine for you. MachTrade consolidates the best brand machines, sales and usage advice, and affordable pricing structure into its online immersive portal. Once delivered and functioning as the hardest working member of your team, MachTrade will supply you with all the on-site maintenance and repair services required to optimize the revenue potential of your valve seat grinding machine.