Introduction

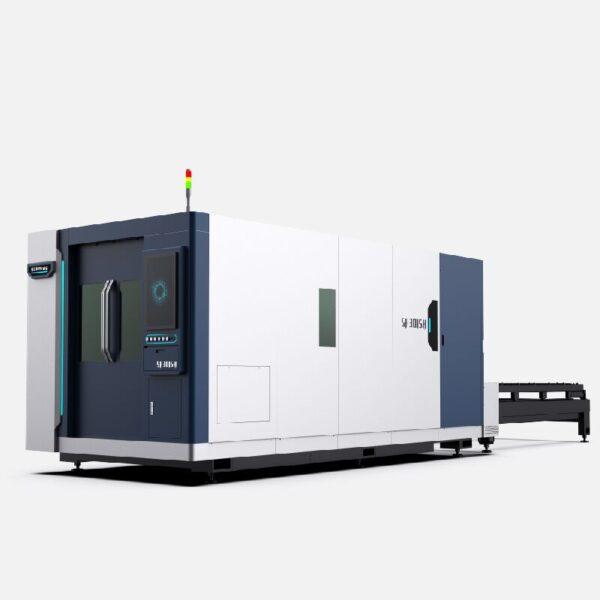

The 4th generation high power fiber laser cutter is mainly designed for high power :6kw to 30kw, it is with full-protection cover, which can prevent the laser radiation and protect the worker safety, reduce the environment pollution; and it is also with auto-exchangeable platforms, which can save the materials loading time, improve the processing efficiency. The exchange platform only takes 20 seconds to complete the exchange. The SF3015H4 high power laser cutter has passed CE/FDA /ETL certifications, which is in line with European and American standards.

Fiber Laser Cutter

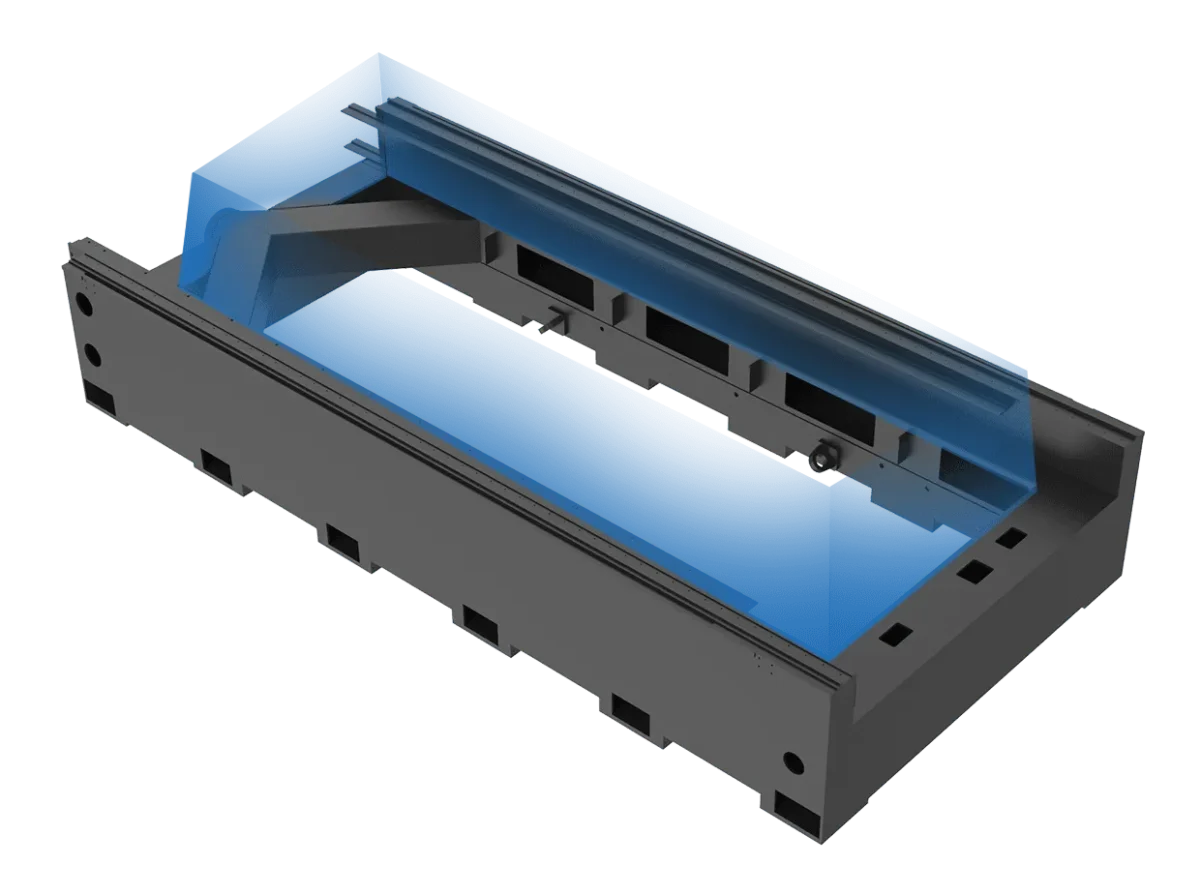

1. Heavy-duty thermally isolated hollow bed

The heavy-duty thermally isolated hollow bed is welded with high-quality steel plates and pipes. After welding, stress relief annealing, secondary aging treatment, and ultra-large gantry milling machine precision processing ensure that the bed has sufficient structural stability and shock resistance. Withstand higher acceleration. There is no connection inside the bed to block heat transfer, avoiding the heat generated by cutting from being transferred to the bed and affecting the processing accuracy. The bed will not be deformed after long-term use, which improves the service life of the equipment.

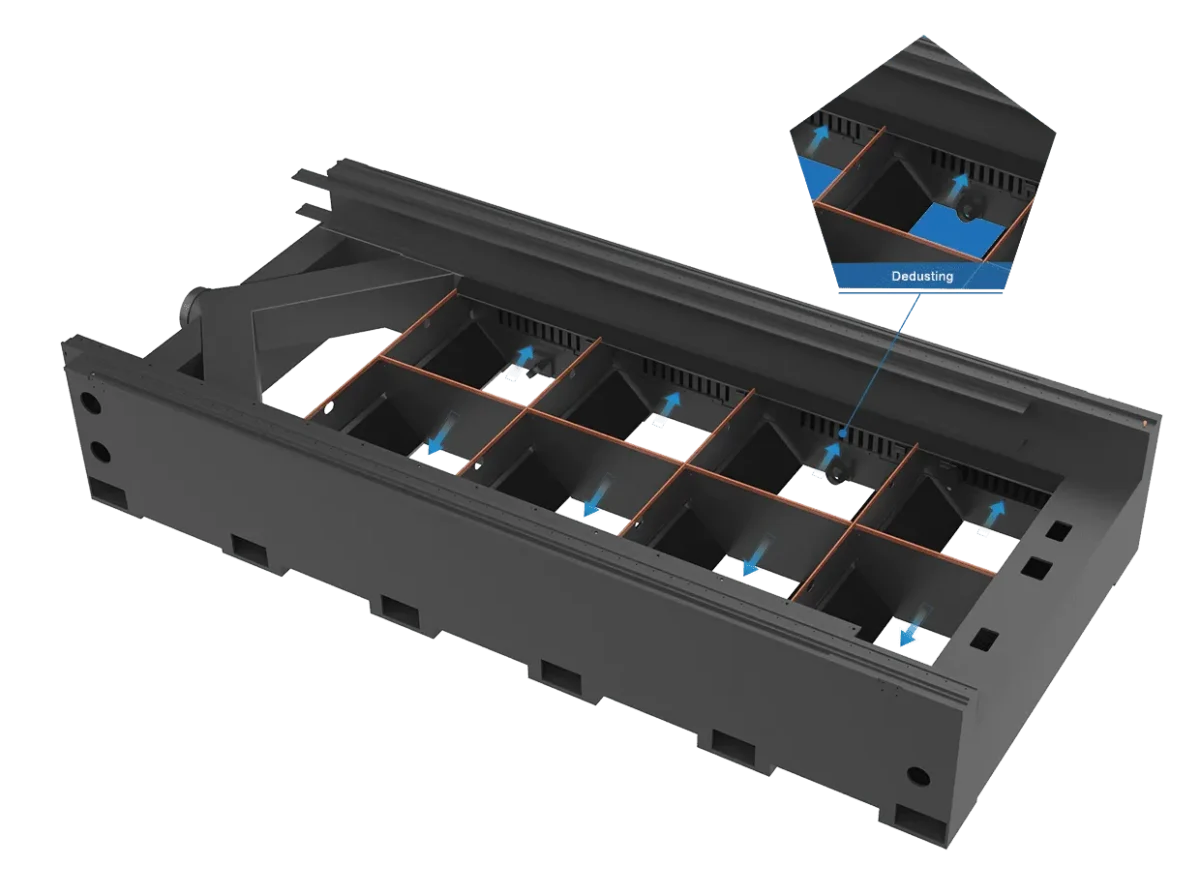

2. Intelligent surrounding spiral negative pressure dust removal

Intelligent surrounding spiral negative pressure partition dust removal system, according to the current cutting position, intelligently switch the air outlet, time-sharing, partition, and sectional air exhaust, and cooperate with the back-shaped sealing structure design at the bottom of the base to realize smokeless cutting.

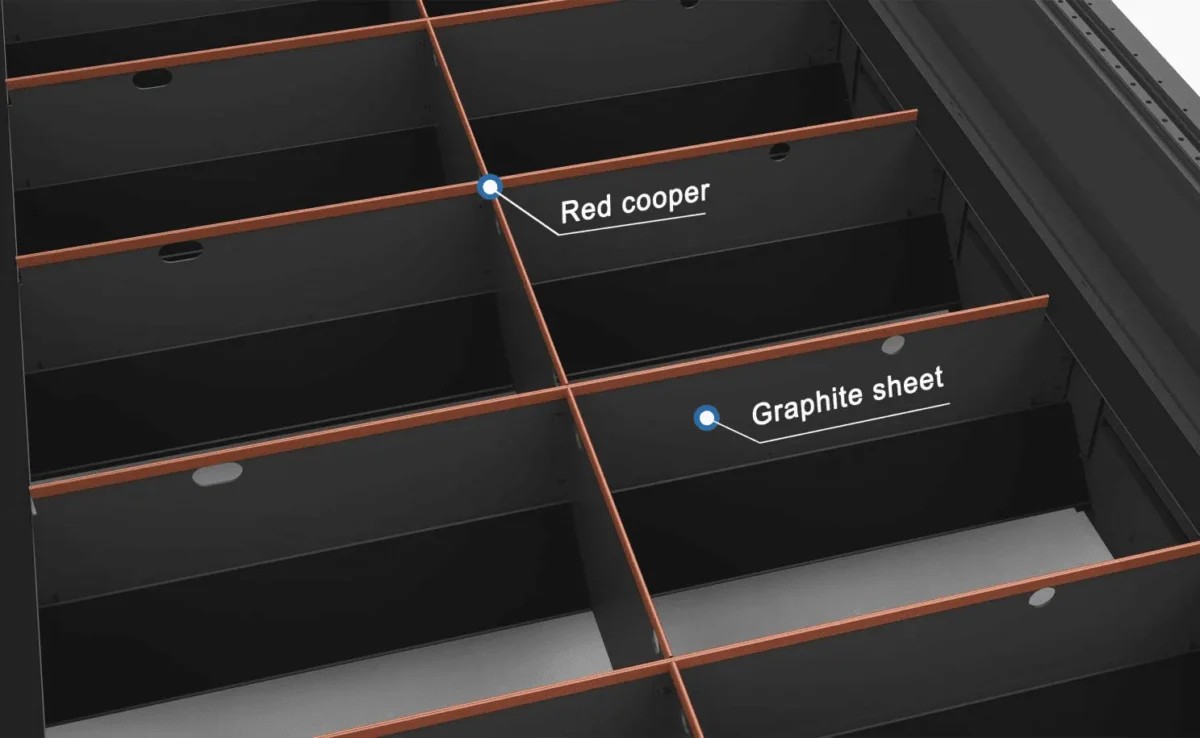

3. Gaphite, copper protection(≥8000w)

The thermal conductivity of graphite is poor, which effectively prevents the machine bed from being deformed by heat and guarantees the service life.

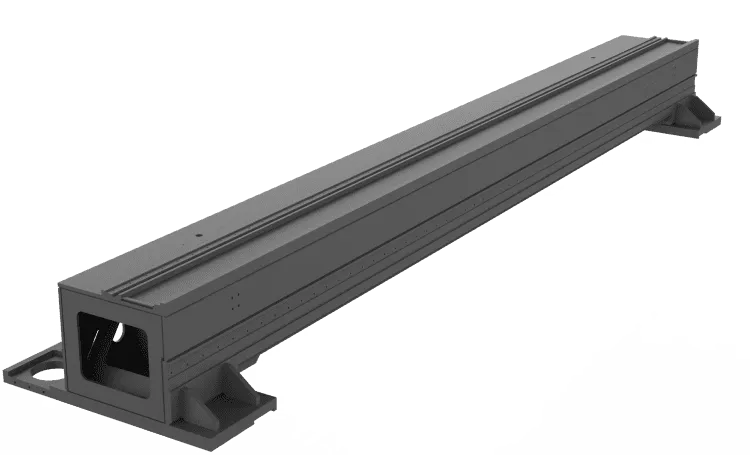

4. Strong Aviation Aluminum Beam

The use of aviation-grade high-strength aluminum alloy beams, light weight, low inertia; built-in triangular reinforced structure, strong rigidity, good shock absorption; rough machining after annealing to eliminate internal stress, and fine machining after secondary vibration aging treatment to ensure Improve the overall strength and stability of the beam.

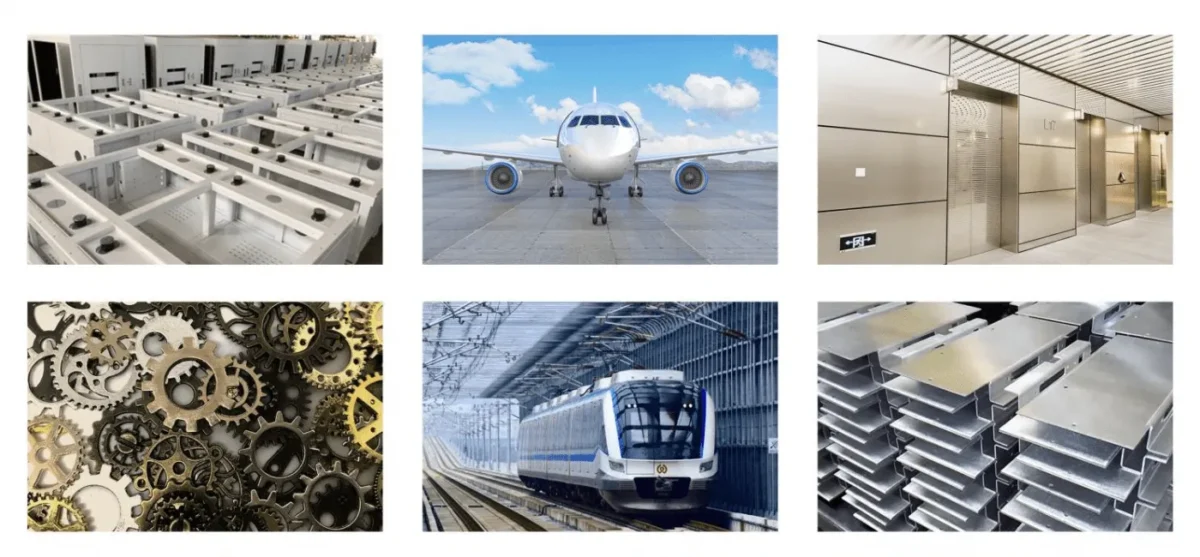

What’s the Industry Applicationof The Fourth Generation Fiber Laser Cutter

The fourth generation fiber laser cutting machine is specialized for sheet metal processing, machinery manufacturing, auto parts manufacturing, electrical manufacturing, elevator manufacturing, petroleum machinery, food machinery, shipbuilding etc.

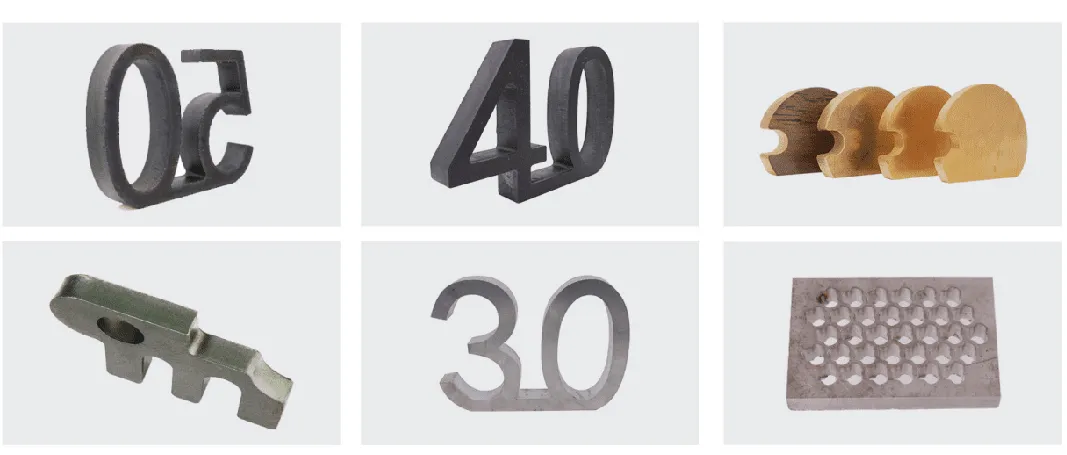

What does the Fourth Generation High Power Fiber Laser Cutter cut?

Carbon steel, stainless steel, aluminum alloy, brass, copper, galvanized sheet, silicon steel sheet, electrolytic sheet, titanium alloy, manganese alloy, etc.