Multi-Material and Multi-Benefit Integration

Comprehensive solution

The U10 supports versatile processing capabilities for profiles, tubes, and metal sheets, allowing seamless handling of diverse steel structures.

Intelligent processing

Equipped with real-time deviation correction, the U10 ensures accurate processing, reducing the need for manual adjustments and the risk of laser head collisions.

Multiple compatibilities

With multiple compatibilities for cutting foundations and Tekla drawings, the U10 optimizes workflow, significantly reducing working costs.

All-in-One Processing

The Ultimate Steel Solution

All-Round Expert

U10 is an all-around expert in the steel structure industry and

it is capable of processing any profile, tube, and metal sheet with ease.

Profile Cutting – One-Stop Solution

U10 can process profiles with widths up to 1500mm, heights up to 600mm, and lengths up to 28000mm. Whether standard or special-shaped profiles, it can provide one-stop processing for perforation, beveling, notching, marking, and cutting.

*Variable diameter beams/widened wing plates/overhead crane beams/longitudinal beams for vehicles/flat-bulb steel processing functions are optional.

Metal Sheet Cutting – With the Blade Worktable

Equipped with the blade worktable, U10 can easily perform perforation, vertical cutting, and bevel cutting on metal sheets.

*The worktable size can be customized up to a length of 28000mm.

Tube Cutting Capability

With the tube processing device, the U10 enables perforation, bevel cutting, intersection line cutting, and accommodates square and round tubes from 200-850mm, as well as round tubes with diameters of Φ100-1200mm.

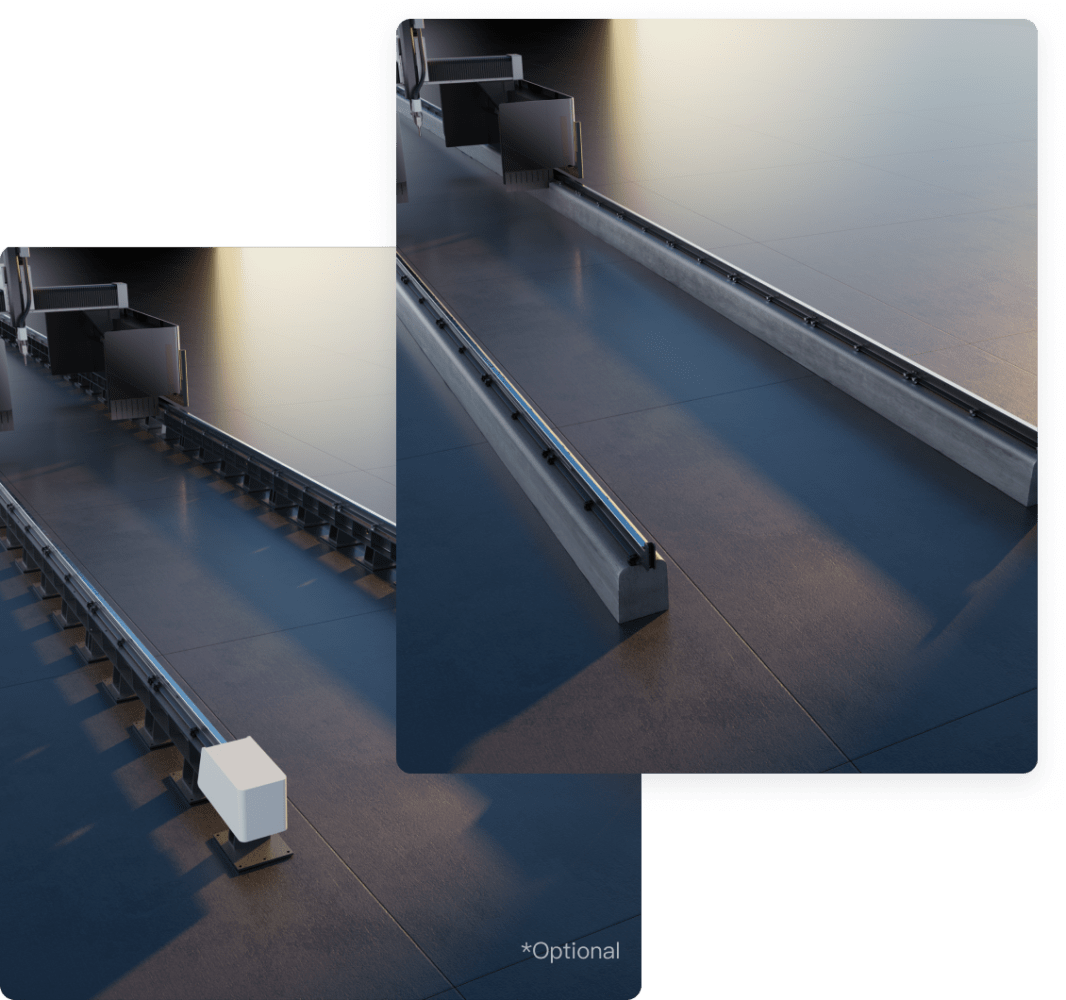

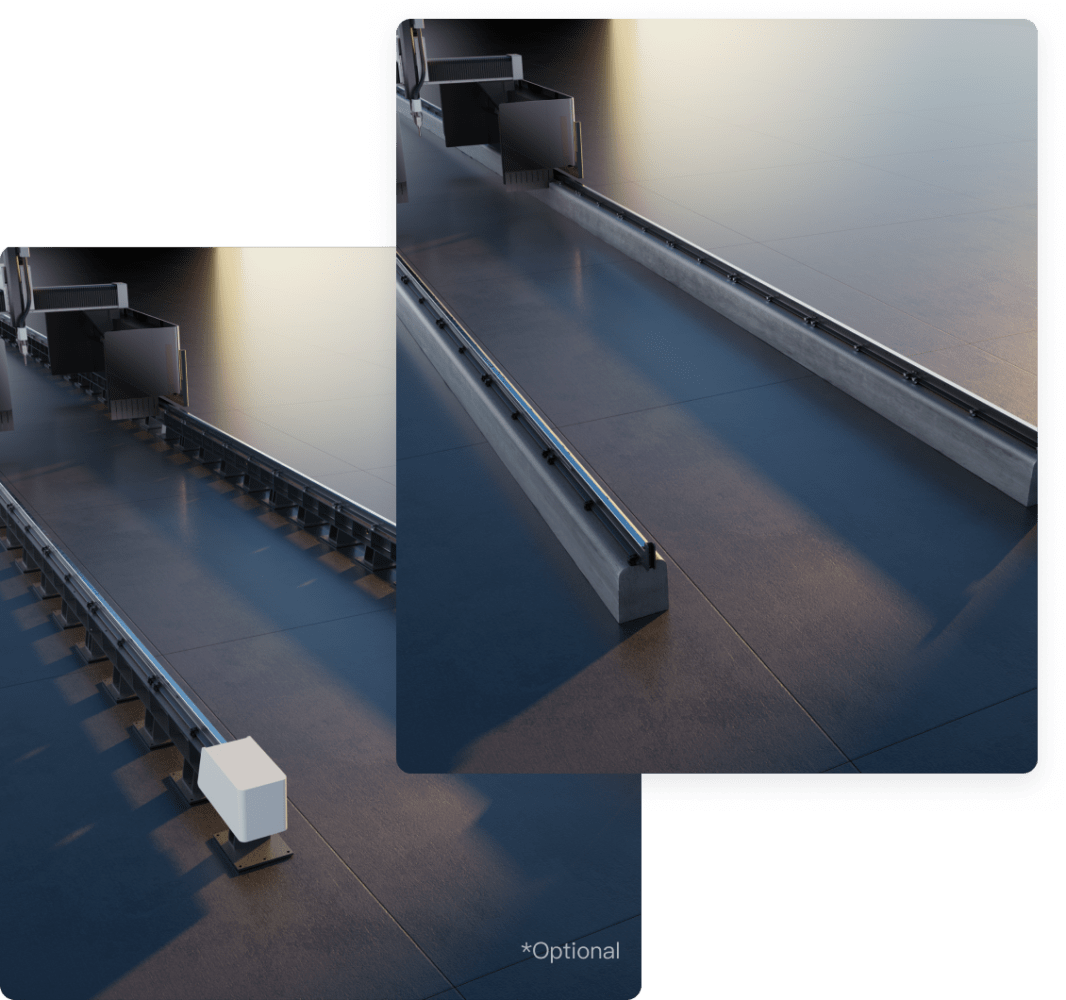

Flexible Foundation Compatibility

U10 is compatible with plasma cutting foundations on the market, eliminating the need to replace the foundation for laser processing equipment. This significantly saves installation time and labor costs, allowing you to quickly enter production.

Optional steel foundation for easier and more flexible installation.

Applicable Industries

Widely applied in industries such as chassis cabinets, ventilation ducts, door and window manufacturing, construction materials, kitchen and bathroom manufacturing, mechanical processing and other industries.

5-Year Warranty

MANGO

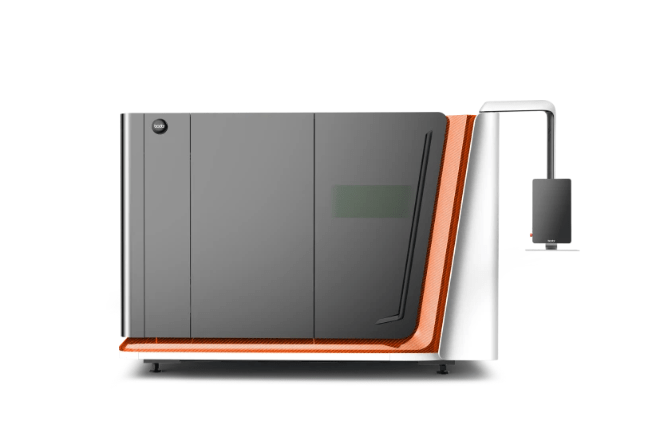

Much-sought-after Wireless Controller

- One-Handed Operation

- Comfortable Grip

- Attachable to anysheet metal

- Embracing the IoT Technological Aesthetics