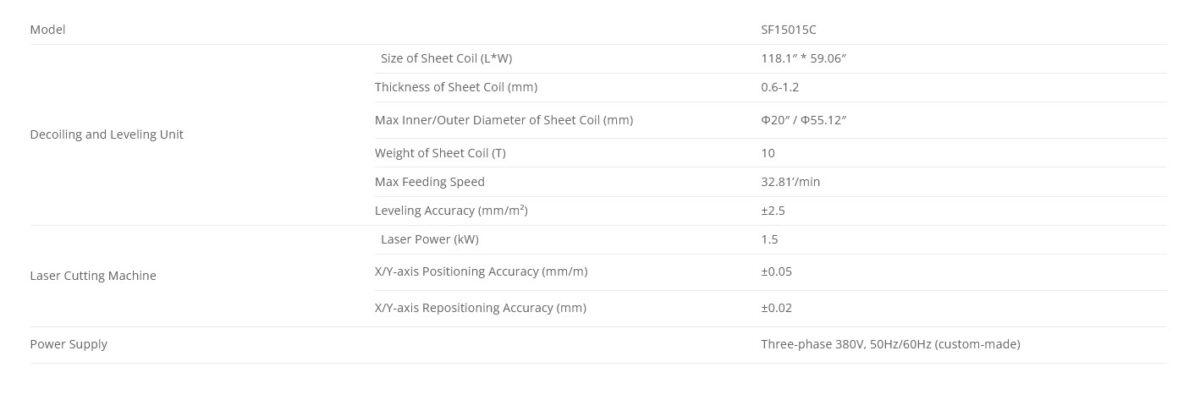

This is an affordable model at low laser power and with open-style structure. Combining decoiling, leveling, feeding and cutting together, this machine has developed into one-stop production line from mere cutting and a sharp weapon to dispel your worry about cutting regular-sized thin coiled sheet.

Fully-automatic Assembly Line

This assembly line is fully automatic and made of automatic loading, decoiling, leveling, feeding, cutting and unloading device. Basically no manual intervention.

* 30% faster than before at least

* Make full use of sheet coil with no waste

Fit to Precisely Cut Super-thin Sheet Coil

We adopt ultra-high-precision positioning correction craft, that is, correcting rollers change sheet coil position according to its width, so as to enable accurate positioning and avoid possible scratch.

* Min thickness of sheet coil: 0.6mm

* Max thickness of sheet coil: 1.2mm

Reduce Costs of Purchase

For users, sheet coil is their first choice while purchasing, rather than cut-to-length steel plate. They may clip by themselves at will. In view of the huge price gap, users will invest less on raw materials.

√ Low-priced sheet coils

× High-priced cut-to-length steel plates

More Eco-friendly and Energy-saving

The control software will choose proper auxiliary gas and its pressure automatically based on actual cutting requirements. In this way, gas consumption is minimized. When it comes to total operating costs incl. power consumption, this machine is 10% less than other same models.

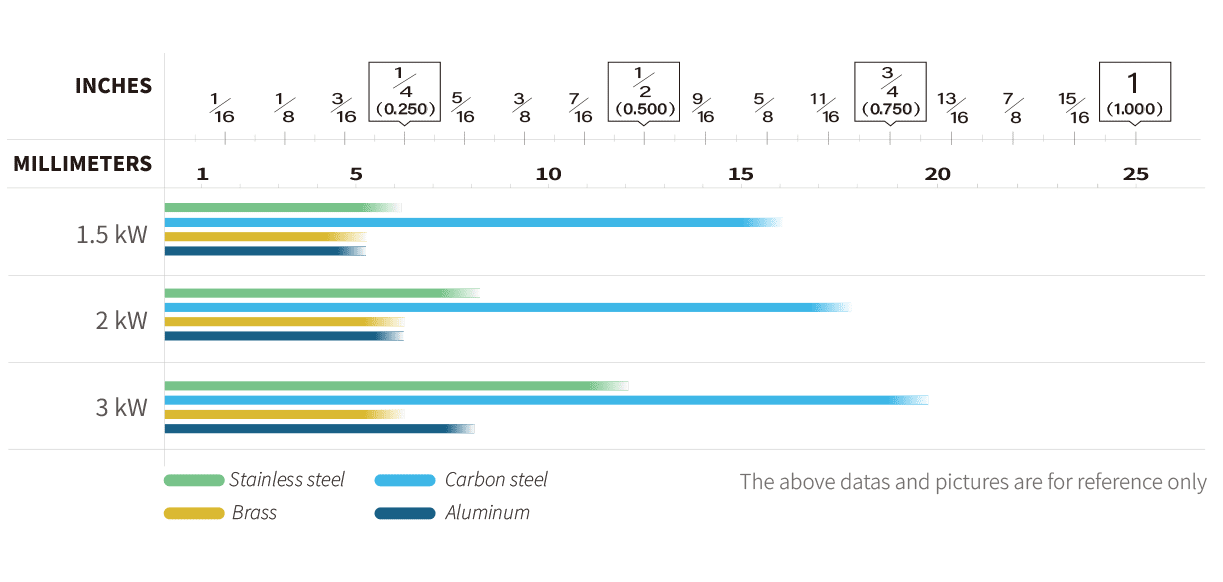

* Laser power: 1.5kW

* Electro-optical conversion rate: 37%

Compact Size with Small Footprint

Unlike other models, this machine units leveler and cutter as one. In addition to their small size, it also helps to transport, install and debug the whole machine.

* Need half footprint at least

* Improve workshop utilization