Your optimal choice for steel coil manufacture

One-stop functioning

Complete steel coil processing in one go. R series production line integrates basically every operation you need for your coil materials, including uncoiling, leveling, and cutting.

Lower material costs

Saving starts with the first cut. Continuous nesting optimally utilizes coil materials, in turn significantly reducing scrap and thus component costs.

High precision

Precise coil cutting is the success factor for efficiency. This is ensured by R series’ misalignment correction function.

Automatic Coil Processing

6 Uncoiling Stations High Production Efficiency

Standard dual-station uncoiler, with up to 6 optional uncoiler stations, allows for loading various materials and thicknesses, without stopping for material changes due to station limitations.

It saves time and effort, improving production efficiency.

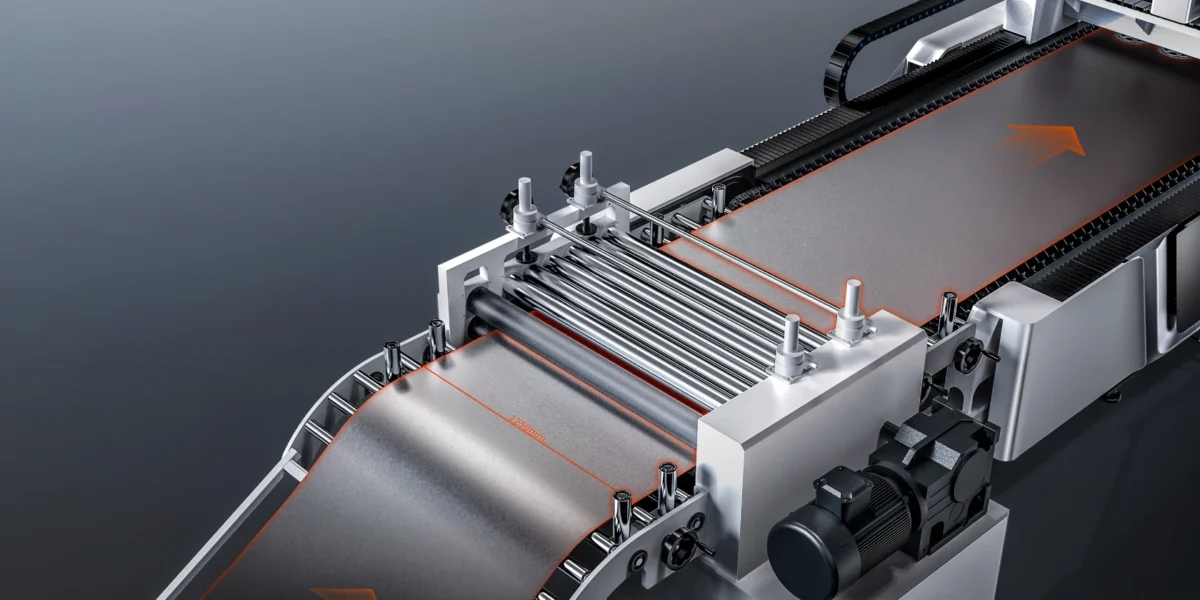

Sheet Edge Anti-Vibrating Stable Cutting

Through the powerful algorithm, it is able to adapt to the high-frequency vibration of thin sheets due to air pressure. The laser head sensitivity is intelligently adjusted, ensuring consistently stable cutting, thereby guaranteeing both cutting quality and efficiency.

Laser Scanning Cutting Brings A Revolution (Optional)

Traditional Cutting

Low energy absorption rate within the cutting area.

Scanning Cutting

High energy absorption rate within the cutting area.

Laser Scanning Cutting Diagram

Fearless High-Reflective Sheets

When cutting high-reflective sheets, it is unaffected by any back reflection, enabling true batch processing of these materials.

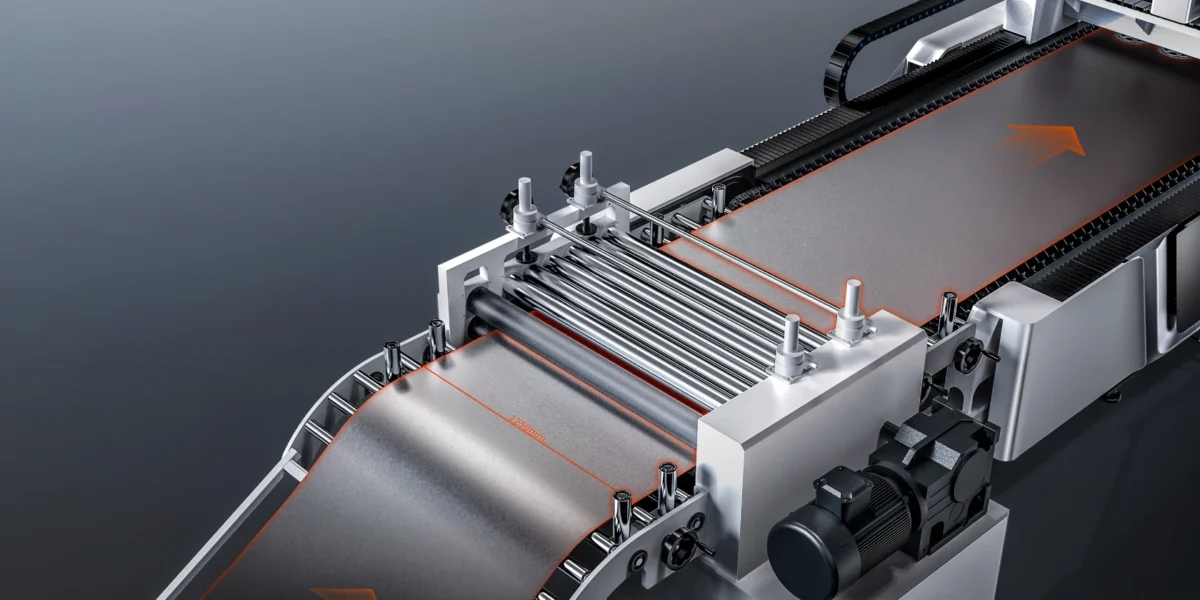

Ultimate Size

The ultimate size reduces redundancy in the coiled sheet laser cutting machine. The 1250mm size perfectly saves floor space.

Workpieces Receiving Platform

Optional workpieces receiving platform transports workpieces timely, facilitating sorting automatically.

Laser Head Intelligent Collision Avoidance

Self-developed servo-following sensors and path avoidance algorithms can accurately sense obstacles in real-time at 360° in the operating path, and plan the obstacle avoidance route in advance to reduce the risk of laser head collision significantly.

5-Year Warranty

Applicable Industries

Widely applied in industries such as chassis cabinets, ventilation ducts, door and window manufacturing, construction materials, kitchen and bathroom manufacturing, mechanical processing and other industries.