Cutting Parameter Auto-Match

Visual comparison of sample parts and cutting parameter auto-match enhance cutting quality, and reduce labor costs.

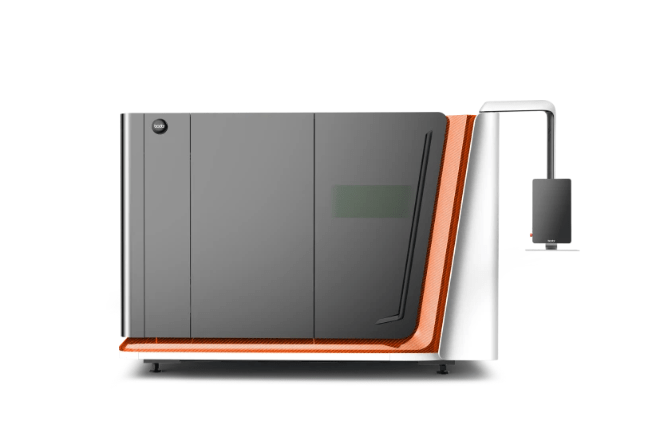

Big things come in small packages

Compact, flexible design

i series increases productivity of your production line without requiring much space. The system has been designed to take up as little floor space as possible.

Eco-friendliness

The fully enclosed design leads to more economical processing and faster performance, with a much lower power consumption.

Efficiency

i series’ compact system demonstrates high productivity thanks to Bodor’s intelligent functions, as they optimize material flow, boost output, and increase the operating safety of the production line.

30% ↑

Overall Performance

Note: The “Overall Performance Improved by 30%”

mentioned above is relative to Bodor’s previous-generation product.

1.5G

Max. Acceleration

It adopts high-performance bus servo motors to achieve the absolute leading dynamic performance (compared with similar products in the market), significantly improving processing efficiency to ensure that every second you invest creates value

The 3rd-Generation Mortise-and-Tenon Welding Bed Frame

Rigidity Increased by – 30%

Structural Strength Enhanced by – 25%

Aerospace Aluminum Beam

Weight Reduced by – 30%

Structural Strength Enhanced by – 25%

Laser Head Intelligent Collision Avoidance

Self-developed servo-following sensors and path avoidance algorithms reduce the risk of laser head collision significantly.

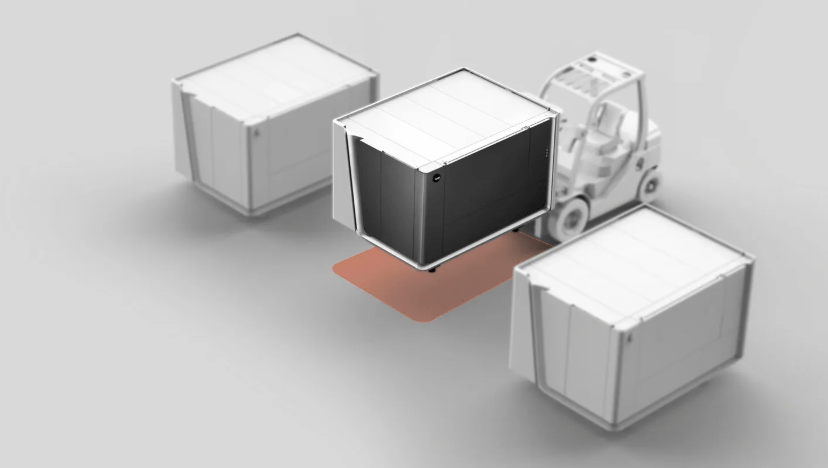

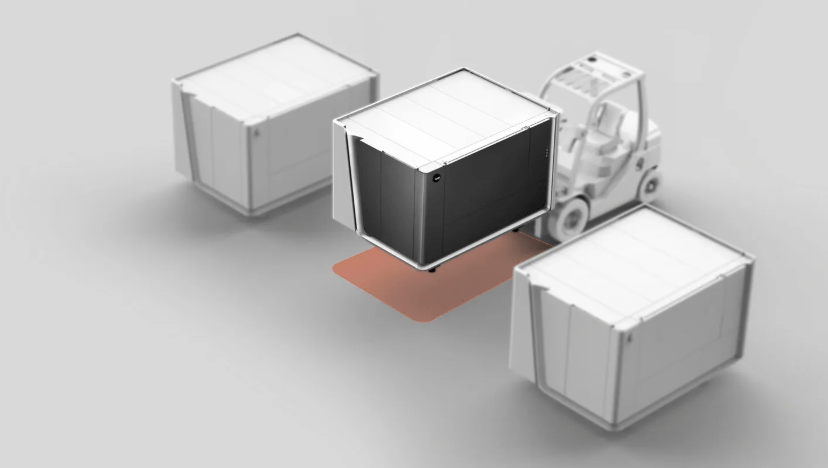

Compact Footprint

Featured as sleek and portable, the i Series is easy to move and ready for operation upon setup.

Enclosure Design

Featured with energy-efficient and environmentally friendly, the enclosure design delivers centralized dust collection and separates operators from machinery, ensuring safety and reliability.

Remnants Layout

By taking a photo of remnants with your phone and uploading the image, you can make the remnant layout a one-click task as the system automatically identifies and quickly locates the corners.

Sheet Edge Anti-Vibrating

The powerful algorithm enables the laser head sensitivity to be intelligently adjusted, ensuring consistently stable cutting, thereby guaranteeing both cutting quality and efficiency.

Bodor +

Bodor+ includes comprehensive services such as auxiliary operations, shared processes, real-time equipment monitoring, regular maintenance reminders, an online accessory store, and one-click fault reporting.

5-Year Warranty

Applicable Industries

Widely applied in engineering, agricultural manufacturing, special purpose motor vehicle manufacturing, mining machinery and coal machinery manufacturing, sheet metal processing and other industries.

Laser Scanning Cutting Brings A Revolution (Optional)

Traditional Cutting

Low energy absorption rate within the cutting area.

Scanning Cutting

High energy absorption rate within the cutting area.

Laser Scanning Cutting Diagram

Fearless High-Reflective Sheets

When cutting high-reflective sheets, it is unaffected by any back reflection, enabling true batch processing of these materials.

MANGO

Much-sought-after Wireless Controller

- One-Handed Operation

- Comfortable Grip

- Attachable to anysheet metal

- Embracing the IoT Technological Aesthetics