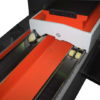

- Cost-iron base(body)

- Wheelhead with fast oleo dynamic feed

- Headstock and tailstock displacement on air cushion

- Electronic adjustable crank speed rotation motor

- Fast-speed powered table traverse (extra)

- Precision incremental in-feed (extra)

- Wheelhead movement secure system

- İncremental electronic measuring device (extra)

- Slides lubrication system

- Work lighting lamp

- Cooling unit with fabric filter system

- 220V Electric power plug on the control panel for foreign uses

- Moveable centering system.(extra)

The Crankshafts Grinding machine boasts various exceptional features. It prioritizes practical usage, high performance, durability, and robust work capability. We’ve engineered this machine with a focus on practicality, ensuring its superior design and quality compared to other brands. For instance, we’ve implemented a pneumatic system for swift center movement, enhancing the machine’s practicality. Additionally, the workhead locking mechanism is highly efficient. The machine integrates hydraulic equipment and a pneumatic system, particularly in the movement of the grinding wheel. Our engineers have pioneered a unique system for the grinding wheel sled, ensuring delicate grinding. Notably, the grinding wheel’s main pivot is mounted in a special bronze bearing. All operations are controlled via the control panel. One standout feature of the machine is its time-saving nature for new operators while providing user-friendliness. Safety for operators is paramount and not a common feature in many other machines.