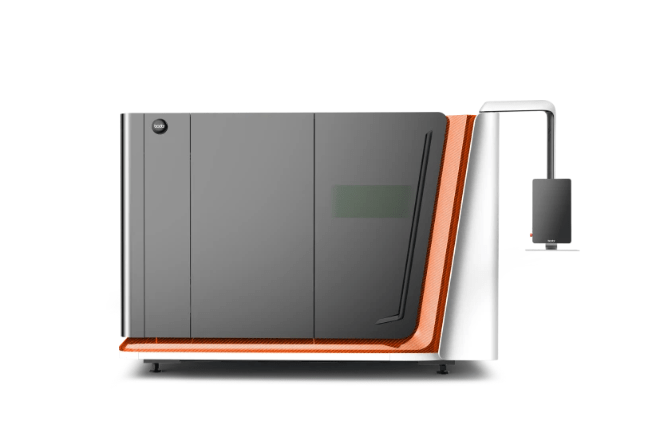

The optimal choice to broaden cutting capabilities

Cost-effective

The AT series minimizes the need for multiple machines by offering sheet and tube-cutting capabilities in a single unit. It is the optimal choice for the best cost-effectiveness.

Easy cutting

The remnants layout and the cutting parameter auto-match help you simplify the cutting process, effortlessly transforming you into a cutting master.

Efficient production

With a fast transmission speed and a high-performance bus servo motor boasting leading dynamic performance, the AT Series significantly increases processing efficiency, allowing you to achieve efficient production.

Cutting Parameter Auto-Match

Visual comparison of sample parts and cutting parameter auto-match enhance cutting quality, and reduce labor costs.

Craftsmanship Shines in Precise Production

The wiring harness assembly is neat and orderly, greatly reducing machine failures and safety hazards caused by disordered wiring. The lifetime maintenance-free rate reaches as high as 98%*, achieving quality and efficiency improvements for you.

The 3rd-Generation Mortise-and-Tenon Welding Bed Frame

The rigidity of the bed frame increased by 30%, and the structural strength enhanced by 25%.

*Data obtained from laboratory analysis

-

30%↑

Overall Performance

Note: The “Overall Performance Improved by 30%”

mentioned above is relative to Bodor’s previous-generation product. -

1.5G

Max. Acceleration

It adopts high-performance bus servo motors to achieve the absolute leading dynamic performance (compared with similar products in the market), significantly improving processing efficiency to ensure that every second you invest creates value.

Aerospace Aluminum Beam

- Weight

30%↓

- Structural Strength

25%↑

Laser Head Intelligent Collision Avoidance

Self-developed servo-following sensors and path avoidance algorithms reduce the risk of laser head collision significantly

Pioneering Modular Worktable Structure

Reduces maintenance costs, ensuring safety and convenience.

Fast Pneumatic Chucks

The pneumatic chucks adopt a direct cylinder push structure. With simple and efficient transmission, it can complete clamping in as fast as 2 seconds. It is easy to disassemble and maintain.

Remnants Layout

By taking a photo of remnants with your phone and uploading the image, you can make the remnant layout a one-click task as the system automatically identifies and quickly locates the corners.

Over Edge Protection

Self-developed servo-following sensors and path avoidance algorithms can accurately sense obstacles in real-time at 360° in the position changes of the tube edges.

Sheet Edge Anti-Vibrating

The powerful algorithm empowers the AT Series to adapt to the high-frequency vibration of thin sheets caused by air pressure, guaranteeing consistently stable cutting.

Bodor +

Bodor+ includes comprehensive services such as auxiliary operations, shared processes, real-time equipment monitoring, regular maintenance reminders, an online accessory store, and one-click fault reporting.

Mineral Cast Anti-Burn Plate

The mineral cast anti-burn plate is heat-resistant and non-conductive, making the machine less prone to deformation, easy to clean, and ensuring a long lifespan.

Applicable Industries

Widely applied in industries such as chassis cabinets, ventilation ducts, door and window manufacturing, construction materials, kitchen and bathroom manufacturing, mechanical processing and other industries.

5-Year Warranty

Laser Scanning Cutting Brings A Revolution

Traditional Cutting

Low energy absorption rate within the cutting area.

Scanning Cutting

High energy absorption rate within the cutting area.

Laser Scanning Cutting Diagram

Fearless High-Reflective Sheets

When cutting high-reflective sheets, it is unaffected by any back reflection, enabling true batch processing of these materials.

MANGO

Much-sought-after Wireless Controller

- One-Handed Operation

- Comfortable Grip

- Attachable to anysheet metal

- Embracing the IoT Technological Aesthetics