Introduction

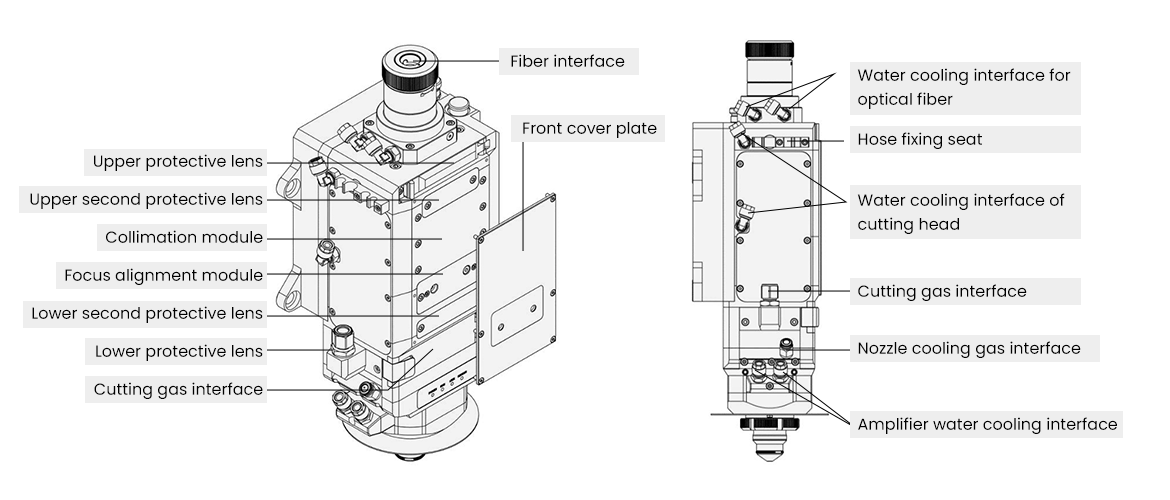

BLT 642H fiber laser head is an intelligent cutting head developed for ultra-high power laser equipment . The new optical path design and optical lens optimization help realize convenient installation, simple debugging, excellent performance, double dustproof, and stable cutting. The Smart Piercing and Auto Recut functions can meet the strict performance requirements of air and nitrogen high-power cutting, effectively improving production efficiency and yield.

Download Product manual

Auto Recut

Real-time monitor the cutting process through internal sensors in the cutting head. If uncut areas are detected, the cutting head automatically retreats and re-cuts, achieving unmanned stable processing.

Smart Piercing

Real-time monitor the perforation process through sensors. After the hole is pierced, cutting is immediately performed without waiting, greatly improving processing efficiency and reducing costs.

Slag-free Cutting

Monitor the laser beam to timely turn it off to realize a slag-free cutting with no gap.

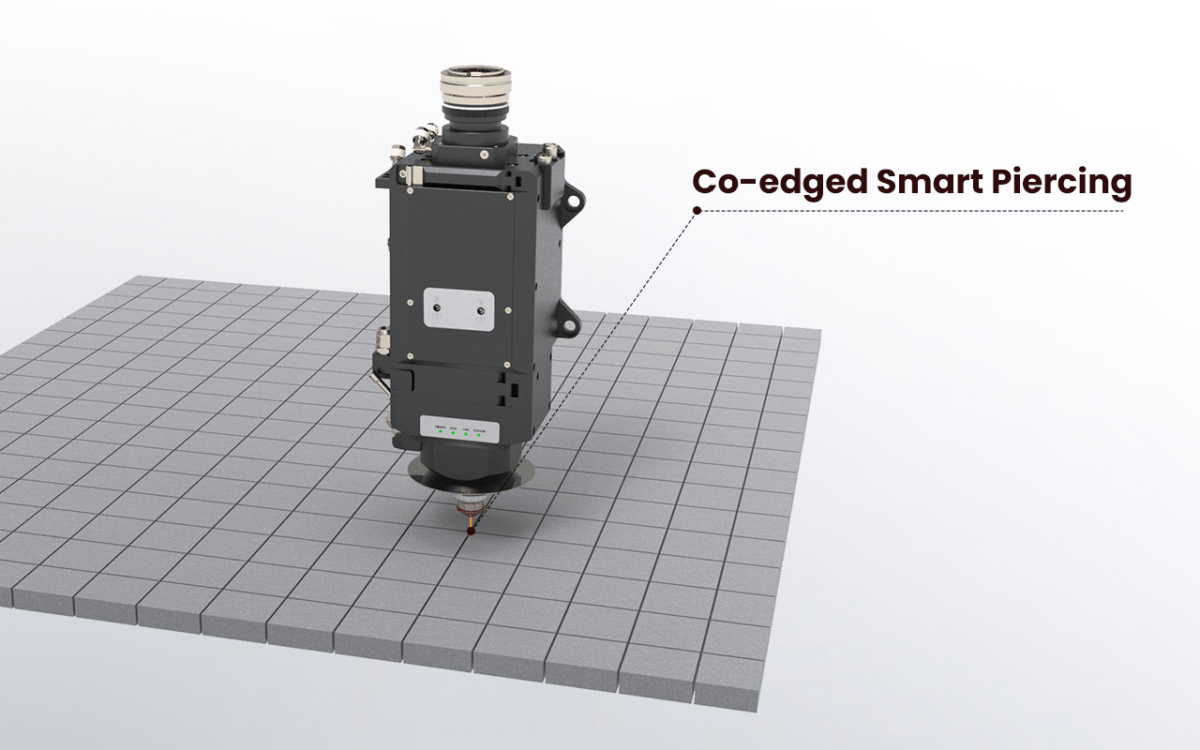

Co-edged Smart Piercing

Intelligently detects whether the co-edge position needs perforation. If the sheet is found to be misaligned, perforation is executed; if not, cut directly, greatly improving processing efficiency.

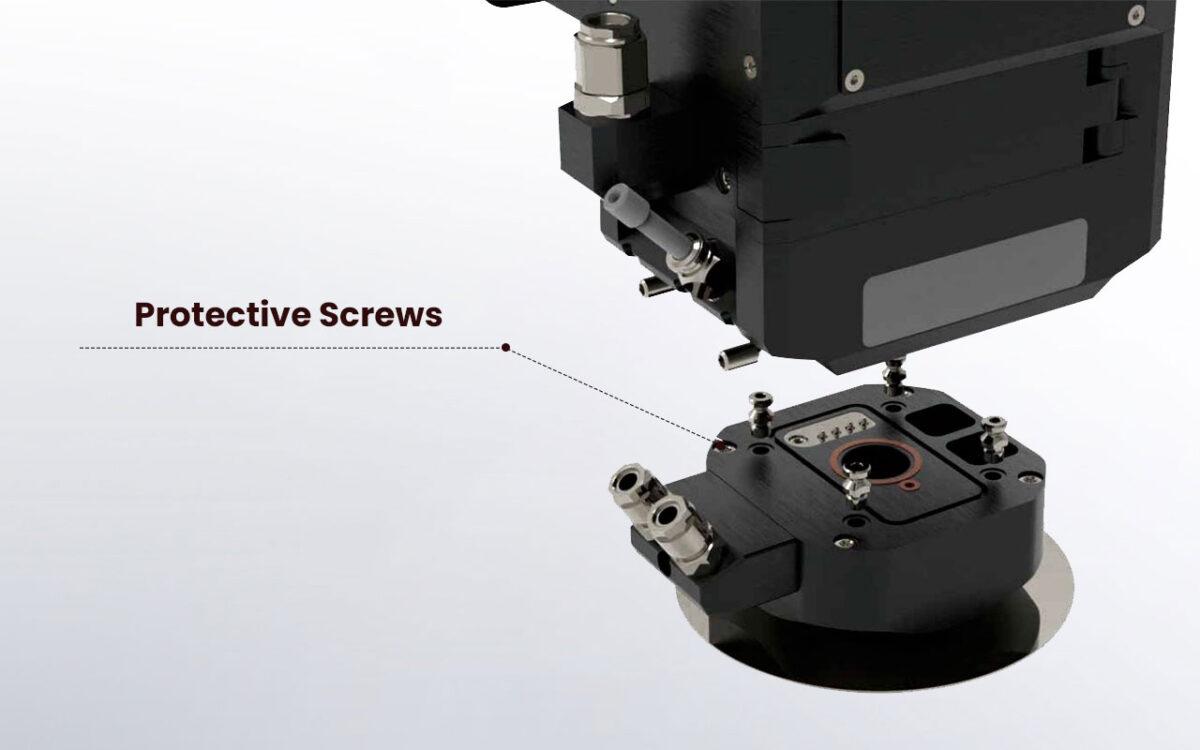

Protective Screws

The anti-collision design of the cutting head effectively reduces the probability of returning to the factory. There is no need for after-sales visits, and customers can replace it by themselves, reducing maintenance costs.

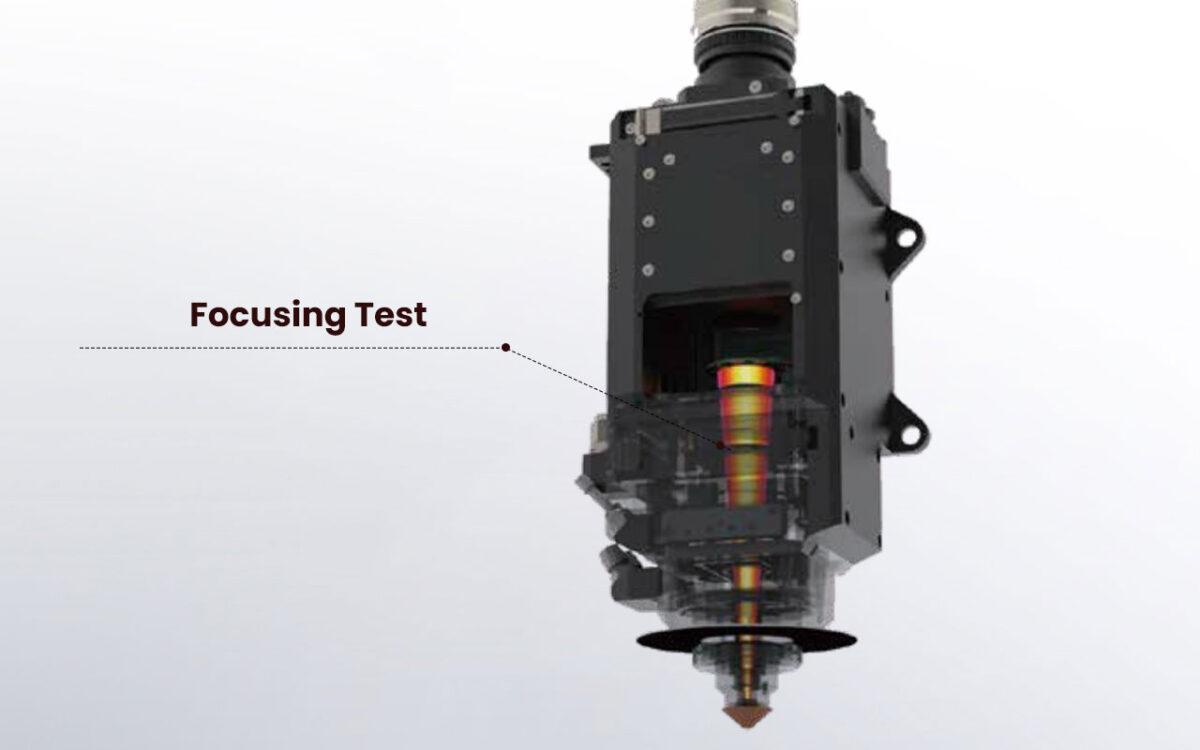

Focusing Test

Real-time monitoring of the astigmatism value of the cutting head cavity can effectively avoid damage to the cutting head caused by excessive astigmatism value and can narrow down the range of lens pollution inspection.

Protective Lens Anti-explosion Monitor

In high-power laser cutting operations, precise and sensitive sensors are crucial. BLT 6 series pollution sensors and system algorithms have been upgraded, and its excellent functions can help customers deal with various working conditions.