Introduction

SFHS3050 ultra-high-speed metal laser cladding machine is a self-developed ultra-high-speed laser remanufacturing equipment. The machine tool can meet the application requirements of coating manufacturing and quick repair of shaft parts of various specifications. The workbench is made of high-strength and high-quality cast iron materials to ensure the stability and accuracy of the machine tool. The high-speed rotating headstock adopts stepless speed change design, which is simple and quick to operate. It has a follow-up powder receiving tray design, which is convenient for quick powder collection.

Main Features of Metal Laser Cladding Machine SFHS3050

- Mechanical Assembly of Metal Laser Cladding Machine

The mechanical assembly of the cladding machine tool is mainly composed of the bed base, the headstock, the column and the beam. Among them, the bed base and headstock are made of high-strength cast iron, which is rough-processed after annealing to eliminate internal stress, and finished after secondary vibration aging treatment. The whole machine has high rigidity and good shock absorption. - High-Speed Laser Cladding Head

The high-speed laser cladding head is equipped with a ring-shaped high-speed cladding nozzle, which can realize the high-efficiency and high-precision cladding processing of the workpiece. The internal structure of the cladding head is completely enclosed to prevent the optical part from being polluted by dust. At the same time, it has a wealth of focused configurations and can be customized to meet the needs of different customers. - Double-Barrel Powder Feeder

The double-barrel powder feeder can realize long-distance powder transportation and meet the requirements of three-dimensional laser cladding and laser rapid prototyping. The system has a hardware failure self-detection function, which can send out alarm information in time when a failure occurs, which is safe and reliable.

Laser Cladding VS Other Processing Method

| Laser cladding | Spraying | Galvanizing | Overlaying Welding | |

| Coating Layer Thickness | up to 25/64″ | up to 3/16″ | 0.1-100μm | 0.1-several mm |

| Workpiece Deformation | Small | Small | Small | Big |

| Bonding Form with Substrate | Metallurgical Bonding | Metallurgical Bonding | Metallurgical Bonding | Metallurgical Bonding |

| Bonding Strength | High | Relatively Low | Low | High |

| Coating Layer Hardness | Controllable | Controllable | High | Controllable |

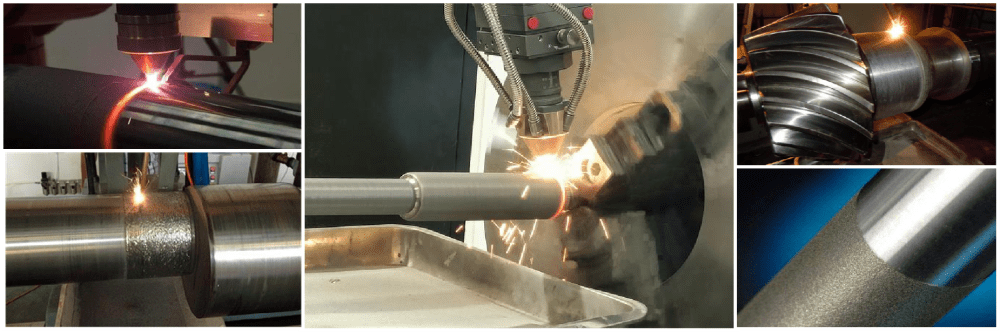

Application of Metal Laser Cladding Machine SFHS3050

Metal Laser Cladding Machine SFHS3050 can repair wear, corrosion, breakage, scratches, scratches, casting defects of various mechanical equipment. Cladding various metals, non-metallic materials such as tungsten carbide and ceramic powder.The surface of the substrate can be modified by acid and alkali – resistance, heat resistance and wear resistance.