Introduction

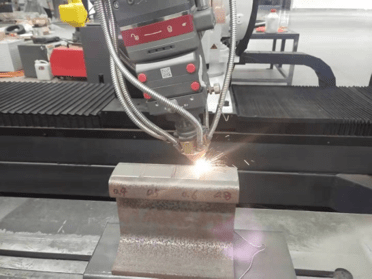

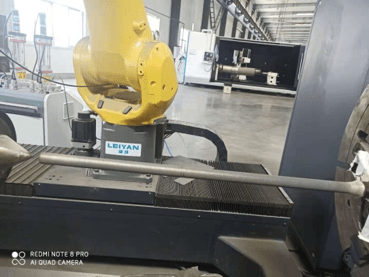

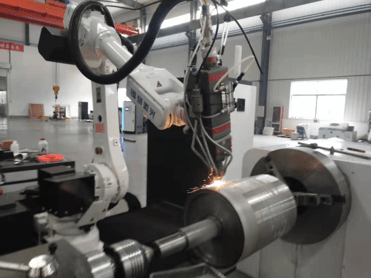

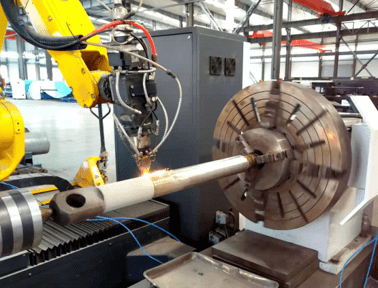

The robot cladding machine is mainly composed of six-axis industrial robot, rollover tooling, biaxial positioner, robot walking axis, workbench, laser, powder feeder, cladding and human-machine interface control system.The robot cladding machine has complete functions, diverse performances and strong versatility. It can realize the cladding of shaft surface, curved surface and special-shaped parts. It is simple to operate and easy to maintain.

Advantages of Laser Cladding Robot Workstation

- The robot cladding workstation is not only suitable for laser cladding processing of simple surfaces such as shafts and planes, but also for processing complex surfaces such as balls and curved surfaces.

- The dual-axis servo positioner is independently designed by senfeng, which can realize the efficient cladding of complex curved surfaces and parts. Its variable position angle is ≤±120°

- The whole processing process adopts computer control. The function of robot is highly integrated and the application system can be switched directly.

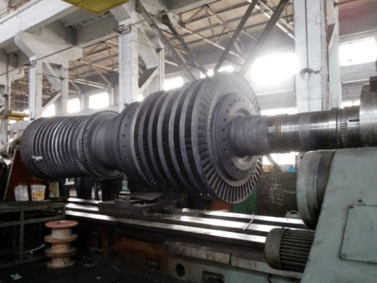

Application industries

The robot cladding workstation is mainly suitable for surface modification of materials, surface repair of products and prototype manufacturing. It is widely used in coal, metallurgy, offshore platform, papermaking, domestic household appliances, automobile, ship, petroleum and other industries.