3 Times Faster than a CNC Press Brake

It is designed for high-volume production running with a higher level of automation and features such as universal bending tools and automatic feeding systems, which reduces manual labor and increases efficiency.

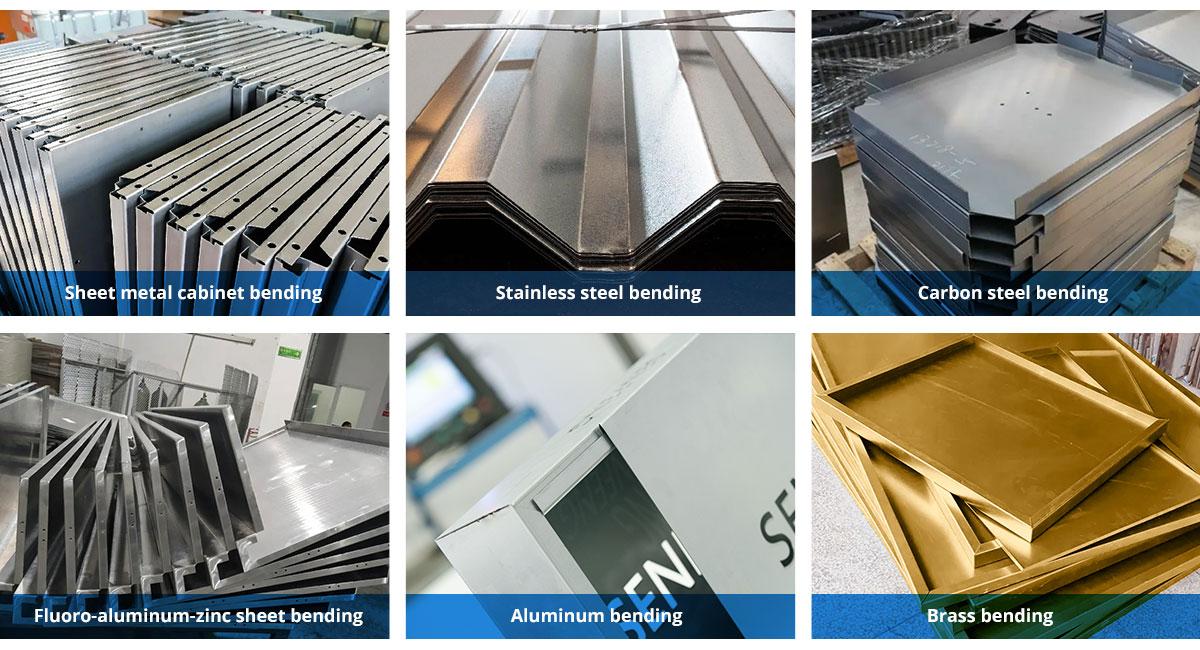

Various Bending Shapes

BDC Series can easily realize basic bending styles such as right angle, acute angle, obtuse angle, etc., and can also realize arc, dead edge, return type, closed type, and other complex sheet metal bending requirements.

Universal Bending Tools

It can adapt to the bending of workpieces with different angles and radii to meet changing production needs, reduce downtime and increase productivity.

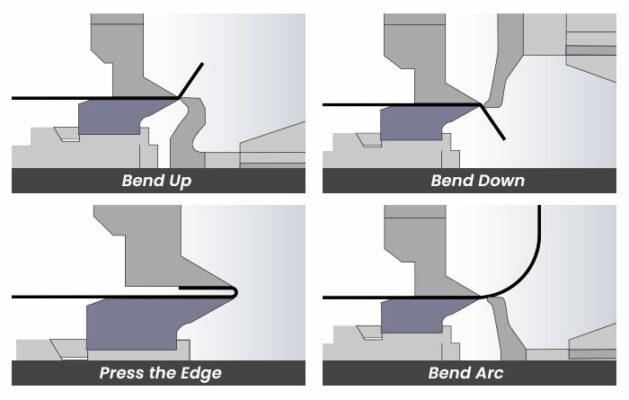

Suction-cup Feeding vs Push-down Feeding

The main difference is the way in which the sheet metal is held in place during the bending process.

Vacuum suction bending is best suited for thin and delicate sheet metal materials that require high precision and accuracy, while downward bending is best suited for thicker and more robust sheet metal materials that require a higher level of force and a consistent bend angle.

CNC Control System

EtherCAT is a high-performance, real-time Ethernet-based fieldbus system that is widely used in industrial automation applications, including bending machines.

- High-speed communication

- Ideal for complex bending applications

- Improved synchronization

- Enhanced diagnostic capabilities