Vertical boring machine with the possibility of plane milling is an excellent offer for any auto repair shop. Versatility combined with precision, simplicity and reliability will increase the productivity of the engine block repair shop. This machine is superior in all respects to similar domestic machines and will compete with European counterparts. The electronic control panel for spindle speed and the ratio of vertical movement to revolutions will allow you to easily reconfigure the boring process for each hole, guided by its parameters and the material of the part, which will easily improve the surface quality after boring.

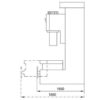

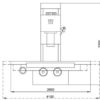

Models TXM170A, TXM200A, TXM250A are different types of vertical boring machine. They have both common characteristics and differences. The functions common to all varieties of these machines consist in boring engine cylinders, milling and grinding surfaces. Their popularity indicates that they cope with their functions at the proper level.

Differences in the numerical part of the name indicate the diameter of the working surface covered by this model of the machine when boring the cylinder block.

These machines are equipped with an electronic panel that allows you to fine-tune the processing parameters and get a clear, expected result. They have a wide range of applications.

TXM170A, TXM200A and TX250A are available in different designs. Always equipped with a standard and optional set of accessories.