- Cylinder Boring Machine Models: The T170A/T200A/T250A series represents the pinnacle of precision engineering in engine maintenance, focused on reconditioning engine cylinders with exceptional accuracy.

- Utilization of Cylinder Boring Bar: These machines rely on the essential tool of the cylinder boring bar, a fundamental component within the automotive industry, to achieve precise cylinder maintenance.

- Versatility for Different Cylinder Sizes: The T170A/T200A/T250A series offers adaptability for various cylinder sizes, making it an ideal choice for workshops and automotive professionals. These machines can accommodate a wide range of bore diameters, catering to diverse engine types and sizes.

- Portable and Convenient: Portability is a key feature, allowing easy movement within workshops. The T170A/T200A/T250A series is a preferred choice for on-site engine repair and maintenance tasks, offering flexibility and efficiency.

- Precision in Automotive Applications: Automotive enthusiasts and professionals value the precision and reliability of the T170A/T200A/T250A series for automotive cylinder boring. These machines are built to meet the stringent demands of the automotive industry, ensuring engine cylinders are restored to their optimal condition.

| Weight | 3300 kg |

|---|---|

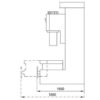

| Dimensions | 230 × 163 × 260 cm |

| Manufacturer | SJMC |

| Model | T170A/T200A/T250A |

| Max. boring diameter, mm | 170/200/250 |

| Max. boring depth, mm | 400/500/500 |

| Max. drilling & reaming diameter | Φ30 |

| Spindle speed | 120-860 r/min |

| Feeding of the spindle | 14-900 mm/min |

| Rapid moving speed of the spindle | 1000 mm |

| Spindle travel | 700 mm |

| Distance between spindle end face and table | 0-700 mm |

| Distance between spindle axis and carriage vertical plane | 375 mm |

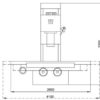

| Max longitudinal travel of working table | 1500 mm |

| Max cross travel of the working table | 200 mm |

| Working table size (W×L), mm | 500*1250 / 500*1500 /500*1500 |

| Quantity of “T” Slot | 5 qua. |

| Boring precision Dimension Precision | H7 |

| Boring precision Boring roughness | 2.5 Ra |

| Main motor | 5.5 Kw |

| Overall dimensions (L×W×H) | 2600*1630*2300 mm |

| Packing dimensions (L×W×H) | 2250*1900*2280 mm |

| N.W. | 3300 / 3500 / 3500 kg |

| G.W. | 3600 / 3800 / 3800 kg |

| Production time, working days | 60 |

Equipment

EQUIPMENT

T170A

T200A

T250A

Universal spindle

–

–

–

Spindle D75 (D 76-170mm)

+

–

–

Spindle D110 (D 111-200mm)

–

+

–

Spindle D150 (D 151-250mm)

–

–

+

Spindle attachment D20 (D21-D42mm) boring bar

–

–

–

Spindle attachment D40 (D41-D60mm) boring bar

–

–

–

Spindle attachment D55 (D56-D80mm) boring bar

–

–

–

Drill chuck

–

–

–

Measuring device for tools

+

+

+

Cylinder locking device

–

–

–

V-Block Boring Device

–

–

–

Device for fixing the cylinder head and block

–

–

–

Milling head D250

–

–

–

Grinding head D320

–

–

–

Digital reader

–

–

–

Splash protection

–

–

–

Ask a question to a specialist