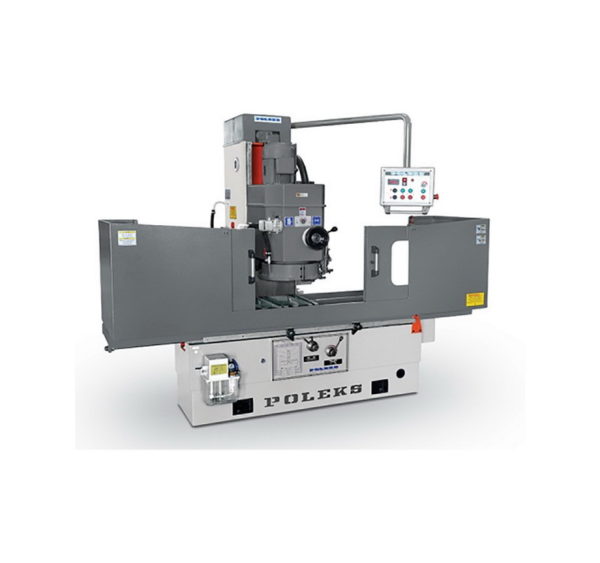

The table is hydraulic and has variable speed control. While the table is in operation, you might adjust the table feed speed as you require. The table feed is out of vibration at even the lowest speeds. Meanwhile, the table slides on prismatic guides for continuous lubrication.

Special sliding covers are designed in order to protect the operator of any explosion of the grinding wheels and prevent the splash of the water that is used along the grinding process. The stone rotating speed can be observed at a digital gauge placed on the control panel